Friday, 29 July 2022

Minew - G1 IoT Gateway

Wednesday, 27 July 2022

NOA Data Service

NOA Data Service

solution specific integration, data visualization and analytics.

they only need the right tools to make it happen.

what they need, when they need it, without the complexity.

|

John

Weber |

||

|

Technical

Lead |

||

|

|

||

|

||

|

||

|

||

|

|

||

|

Indoor Air Quality sensors - Milesight

Background

Did you know that we spend almost 90% of our time in indoor activities? Because the majority of our time is spent indoors, take a moment and get to know the indoor air you breathe! As previous research shows, Indoor Air Quality (IAQ), especially CO2 monitoring, is important for occupants’ health. So good ventilation in the building is indispensable. However, indoor air pollutants negatively affect people’s health conditions and working performance. High carbon dioxide level (CO2) intensities could result in Sick Building Syndrome (SBS) symptoms, which makes it the marker to evaluate air quality and ventilation performance.

Due to the health effects of poor IAQ, especially associated with a high concentration of CO2, it is necessary to monitor the CO2 in room air in buildings to raise the ventilation frequency in time, which can help reduce people’s risk of indoor health concerns in advance, as well as reduce energy wasting. In this circumstance, Milesight provides the IAQ Sensor to monitor the concentration of CO2 in room air.

Why Milesight IAQ Sensor

Milesight IAQ Sensors are designed for indoor scenarios such as buildings, classrooms, offices, supermarkets, hospitals, etc. They can monitor the air people breathe as occupancy fluctuates and people interact. IAQ Sensors can detect not only CO2 but also temperature, PIR, TVOC, CO2, barometric pressure, HCHO, PM2.5 & PM10, O3, humidity, and light. Users can select 3-in-1, 7-in-1, and 9-in-1 sensors based on their needs.

Challenges

- Energy Wasting

There’s a large amount of energy used by activating the ventilation system if one needs to regulate the airflow in a building.

- Delayed Outcome

The outcomes of monitoring IAQ are usually generated over long periods on average, which may lead to a late response because the exposure has already occurred.

Solution

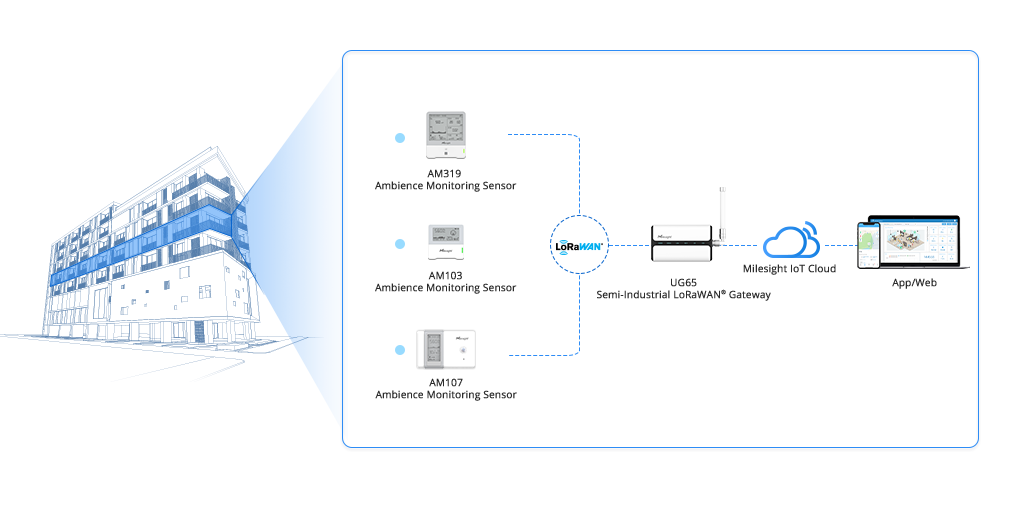

By applying Milesight IAQ Sensors in buildings, occupants can get to know the CO2 level in room air as well as various attributes correlated to indoor air quality, such as humidity, temperature, TVOC, etc., through a 4.2-inch E-ink screen. Besides, the traffic light status indicator could help users understand their environment visually. Once the CO2 intensities reach the threshold, the Milesight IAQ sensor will immediately send out the alert to Milesight IoT Cloud through UG65 LoRaWAN® Gateway. So that it can offer users an indication of increasing the ventilation frequency.

What makes this solution even more attractive is the intelligent trigger system of Milesight IoT Cloud. It visualizes field data and enables users to monitor and control remote assets on an intuitive dashboard. In this solution, Milesight IoT Cloud can automatically turn on the individual fans, ventilation system, and any other equipment for ventilation with the help of the ventilation controller.

Featured Product

Benefits

- Long-term Health Benefits

Monitoring the CO2 in room air in real-time and increasing ventilation rates in time could help decrease the prevalence of SBS symptoms and drive long-term health benefits.

- Energy Efficiency

No need to turn the ventilation system on all the time. Users can only activate it when an alert is received by which can help save energy and further reduce carbon emissions, thus facilitating a more sustainable way to live.

- To Curb the Spread of Disease

During the Covid-19 pandemic, the IAQ sensor could help people to live in safer and healthier facilities through real-time air quality monitoring and alert.

- Productivity Improvement

Within the acceptable range of CO2 levels and with the improvement of IAQ, people’s ability to concentrate and problem-solving can be significantly enhanced.

This article, attributed to Milesight can be found at Milesight

Milesight products can be purchased at IoTdc, please contact:

|

Theo Barnard |

||

|

Head of Product |

||

|

|

||

|

||

|

||

|

||

|

|

||

|

Tuesday, 26 July 2022

Cold Chain Monitoring via LoRaWAN

Cold Chain Monitoring via LoRaWAN

Background

The cold chain ensures that the food, beverages, medication, and volatile chemicals are still safe to use after they reach the consumers. To do this right, temperature is a profoundly vital factor. Bacteria grows quickly and could taint consumable goods if the transporters do not keep them at the right temperature. Cold rooms, warehouses, order assembly points and loading docks all have specific temperature profiles that must be monitored and maintained based on the products being stored or transported. Adopting a reliable and accurate PT100 temperate sensor may be one of the best ways to ensure the efficacy and safety of temperature-sensitive products.

Why PT100

The PT100 temperature sensor is an instrument that converts temperature variables into a standardized output signal that can be transmitted. They have been used for many years to measure temperature in cold chain, laboratory and industrial processes, and have developed a reputation for accuracy, repeatability, and stability.

Challenges

- Control at Specific Level

Cold chain Logistics service providers need to offer controlled environment, refrigerated, frozen, deep freeze and cryogenic freezing services, which can be complex, as each has its own temperature requirements and application.

- Maintenance in Transit

Shipments pass through a variety of environments and handlers. Considering any deviations in temperature could affect the safety of products, it’s difficult to manage complicated cold chain effectively without real-time information.

Solution

An industrial temperature monitoring system for cold chain can be useful on any type of equipment with moving parts and components. Milesight offers two workable solutions tailored to customers’ needs. For new LoRaWAN solution deployment, the EM500-PT100 Industrial Temperature Sensor would be a good candidate. It is a three-wire RTD design and performs perfectly as cold as -328 °F (-200 °C).

By transporting data from EM500-PT100 to UG65 gateways, real-time monitoring and alerts of temperature on the IoTdc NOA Data Service are achievable easily.

For upgrades to existing deployments, the UC300 IoT Controller could be a better fit. Besides the 4~20 mA and 0~10 V type analog interfaces, the UC300 firstly adopts 2 RTD inputs for accepting and converting resistance signal of 2/3 wires PT100 sensors into 4-20 mA current signal with a range from -200°C to 800°C.

The UC300 IoT Controller supports 4G and LTE as well as LoRaWAN. So, the selection of technology would be more flexible.

This article, attributed to Milesight can be found at Milesight

Milesight products can be purchased at IoTdc, please contact:

Theo Barnard | ||

Head of Product | ||

|

Most prevalent POC’s in world of IoT 2023

Most prevalent POC’s in world of IoT 2023 There are countless use cases being tested via POC (Proof of Concept) in the world using IoT (Inte...

-

Milesight WS101 LoRaWAN button Easy usecases for LoRaWAN button from Milesight WS101 The LoRaWAN button from Milesight is an extremely ver...

-

Setting up a POC - Proof of Concept or POV - Proof of Value, for IoT devices can be extremely time consuming. If your development team doesn...